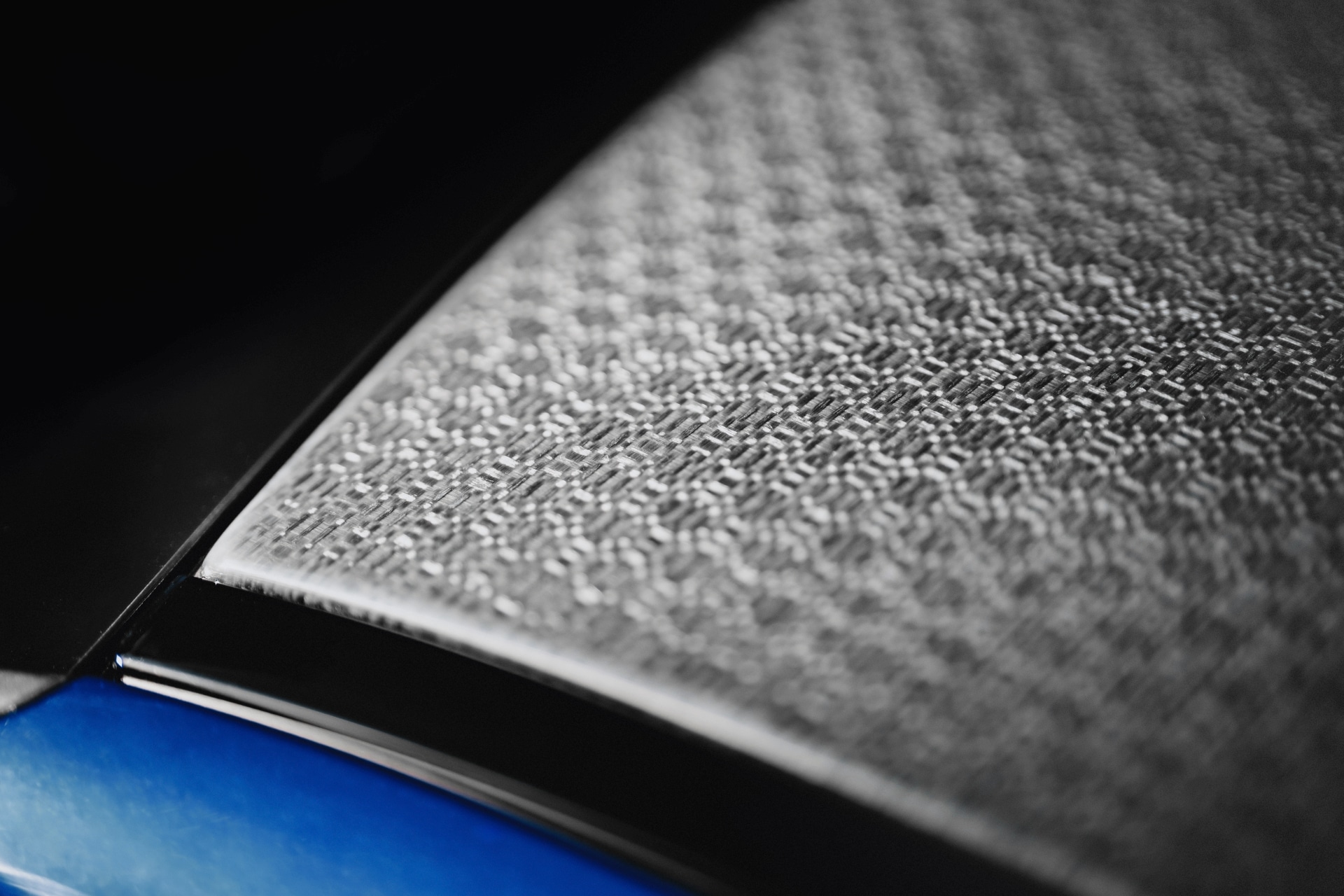

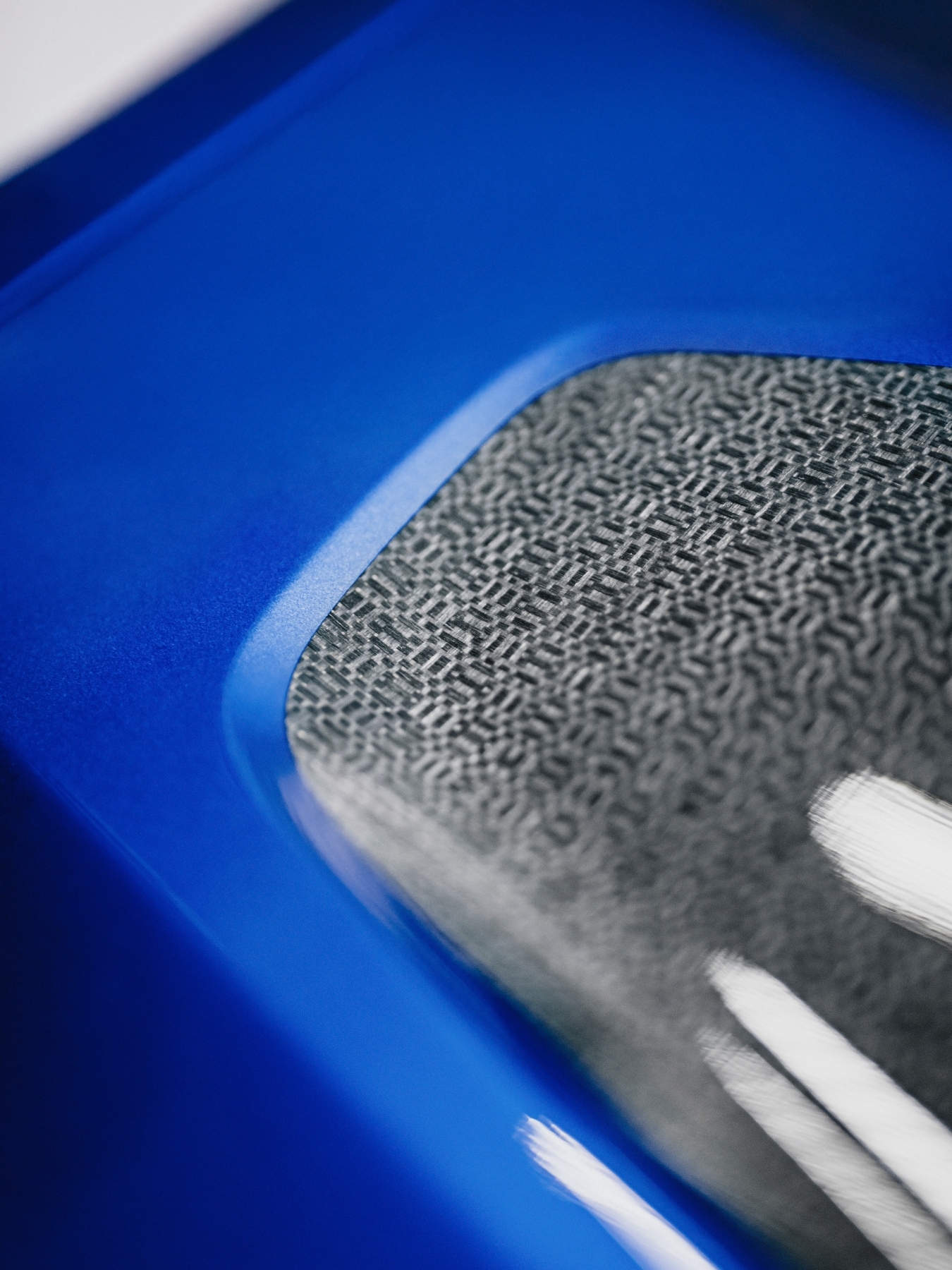

In racing, every hundredth of a second counts, sometimes even every thousandth. Lightweight construction is therefore an important factor in making the vehicle as dynamic as possible. In addition to aluminium components, GRP (glass fibre reinforced plastic) and CFRP (carbon fibre reinforced plastic) have been the materials of choice for reducing weight. Through several years of development work and intensive research, the BMW Group has now brought another material to series production that combines optimum stability with low weight: natural fibre composites.

RENEWABLE AND STRONG.

The development of flax-based lightweight components has been ongoing for several years in collaboration with Swiss cleantech company Bcomp. Through this cooperation, the BMW Group aims to further reduce CO₂e emissions in future vehicle models while at the same time increasing the performance of the cars. This applies in particular to high-performance models from BMW M.

Material tests show that flax fibres are particularly suitable for visible exterior and interior components. Even the high requirements of roof structures in total vehicle homologation are met by natural fibre composites. The widest possible range of applications is relevant because the use of this material instead of CFRP in future models will achieve a CO₂e reduction in production of around 40%, with additional end-of-life considerations.

Natural fiber composites are a vital element of innovative lightweight solutions in motorsport, allowing for a reduction in CO₂e emissions in the manufacturing process. Natural fiber is an innovation that perfectly exemplifies BMW M’s claim ‘Born on the racetrack. Made for the streets.’

SUCCESSFUL ON RACETRACKS SINCE 2019.

SUCCESSFUL ON RACETRACKS SINCE 2019.

The innovative high-performance materials made from natural fibres were first used by BMW M Motorsport in Formula E in 2019. Since then, these components have also successfully replaced carbon parts in the BMW M4 DTM and M4 GT4. In the BMW M4 GT4 EVO, for example, the reinforcement solutions developed by Bcomp are used throughout the interior, on the dashboard and centre console, as well as on the exterior for the bonnet, front splitter, doors, boot and rear wing.

The lightweight materials once again impressed in 2025 in several BMW M4 GT4 EVO cars at the 24-hour race on the Nürburgring – the ultimate test of performance for the new technology.

With the now confirmed use of this innovative material in future series production vehicles, BMW M is bringing another high-performance technology from the racetrack to the road – while simultaneously reducing CO₂e emissions in production.